GAIL (India) Limited has awarded iFluids Engineering to carry out Quantitative Risk Assessment (QRA) study for GAIL–Petrochemical Complex, in Pata.GAIL (India) Limited the country’s premier Natural Gas Marketer & Transporter, diversified into the manufacturing and marketing of downstream HDPE & LLDPE from natural gas cracking at its Pata (Uttar Pradesh state, India) unit from 19th March 1999.

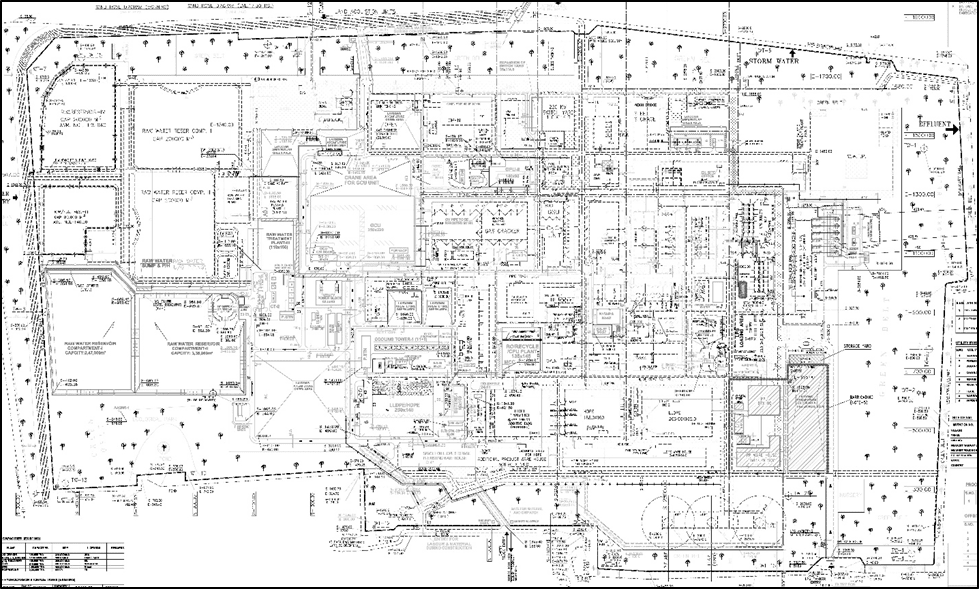

This Petrochemical complex is by the side of Delhi-Howrah main railway track and 83 Km away from Kanpur towards Delhi.This Petrochemical complex recovers ethane-propane (C2/C3) from natural gas from Vijaipur through the HVJ pipeline for producing polymers. Conversion of ethane-propane (otherwise used as fuel) from natural gas gives remarkable value addition. The initial capacity of HDPE and LLDPE was 2,60,000 MTPA.

Further, GAIL has augmented the installed capacity by putting new Gas Cracker Unit, Linear Low Density Poly Ethylene (LLDPE) /High Density Poly Ethylene (HDPE) Plant of capacity 4,00,000 MTPA and associated utilities and offsites.

SCOPE

QRA study covers the following facilities

• Integrated Gas Processing unit (GPU).

• Gas Sweetening unit.

• Gas Cracker unit I

• Gas Cracker unit II

• HDPE-I unit.

• HDPE-II unit.

• LLDPE I unit

• LLDPE II unit

• Butene plant (Old).

• Butene –I unit. (New) 18

• LPG unit

• Storages

OBJECTIVE

The Objective of this study is as follows

- Calculation of Physical effects which include Estimation of Jet Fire, Pool Fire heat radiation distances, Flammable gas dispersion distances, overpressure explosion distances and Toxic dispersion

- Evaluate the potential risk levels for personnel due to accidental release of hazardous materials from loss of containment scenarios from the facilities and to demonstrate that individual risks and Societal risk are within the broadly acceptable regions.