What is Quantitative Risk Assessment (QRA) ?

Quantitative Risk Assessment (QRA) is a tool used for risk analysis of a system or process in a systematic manner. It’s employed in several industries, including Power generating, Oil and gas, and Transportation. QRA define hazards to employees working on various systems, which are then compared to safety requirements and evaluated for acceptability. QRA is often used to predict public safety threats.

Types of Hazards

There are three main types of Hazards:

- Individual risk is the risk of a single individual being harmed or killed by a particular hazard.

- Societal risk is the risk of a group of people being harmed or killed by a particular hazard.

- Consequence impact is the risk of a particular hazard causing a certain amount of damage.

| Risk type | Definition | Example |

|---|---|---|

| Individual risk | The risk of a single individual being harmed or killed by a particular hazard. | The risk of a person being killed in a car accident. |

| Societal risk | The risk of a group of people being harmed or killed by a particular hazard. | The risk of 100 people being killed in a chemical plant explosion. |

| Consequence Impact | The effect of a particular hazard causing a certain amount of damage. | The effect of flood causing $1 billion in damage. |

Individual risk, society risk, and consequence impact are all significant considerations when making safety and risk management decisions. The most important form of hazard will be determined by the circumstances. When developing a new chemical plant, for example, it is critical to consider both the individual danger to workers and the societal risk to the surrounding community.

Why QRA Study is needed?

The Quantitative Risk Analysis provides valuable insights into the plant’s risk profile, distinguishing and ranking the areas where failures could be hazardous to the operators, members of the general public/community nearby, the setting, and hence the quality itself. QRA offers a foundation for higher cognitive processes in the design and operation of the plant, and it should even be required to indicate that assets are suitable for the intended operation.

The objective of a QRA study

- Identify and assess the hazards associated with a system or activity.

- Determine potential consequences of hazards, including the likelihood and severity of accidents.

- Evaluate the Risks to people, property, and the environment.

- Recommend measures for Risk mitigation

Technical Challenge:

Risk assessment is an overall method of distinctive and analyzing risk, and evaluating however it would be changed to take care of applicable levels of safety and to satisfy the regulative, company norms / criteria.

It is vital to spot risks in industrial workplaces so as to shield the plant staff, the folks within the close space, the setting and therefore the plant assets. Demonstration of acceptable risk levels is usually a demand for any single or several facilities like chemical production and process facilities, high pipelines or storage and transportation sites for Gas / Oil.

Difference between Qualitative and Quantitative risk analysis

Qualitative Risk analysis

The process of identifying, evaluating, and prioritizing hazards based on personal preferences and experience is known as qualitative risk analysis. It is frequently utilized in the early stages of a project or effort to gain an overview of the risks involved.

Quantitative Risk analysis

The process of identifying, assessing, and prioritizing risks based on numerical data and statistical analysis. It is often used in later stages of a project or initiative to develop more detailed and accurate risk estimates.

| Characteristic | Qualitative risk analysis | Quantitative risk analysis |

|---|---|---|

| Data used | Subjective judgment and experience | Numerical data and statistical analysis |

| Level of detail | General | Detailed |

| Results | Not Numerical | Numerical |

| Complexity | Less complex | More complex |

| Cost | Less expensive | More expensive |

When QRA ought to be done?

QRA techniques is administered to spot potential hazards to an asset together with plant, method and personnel; & the proper time to travel for QRA when;

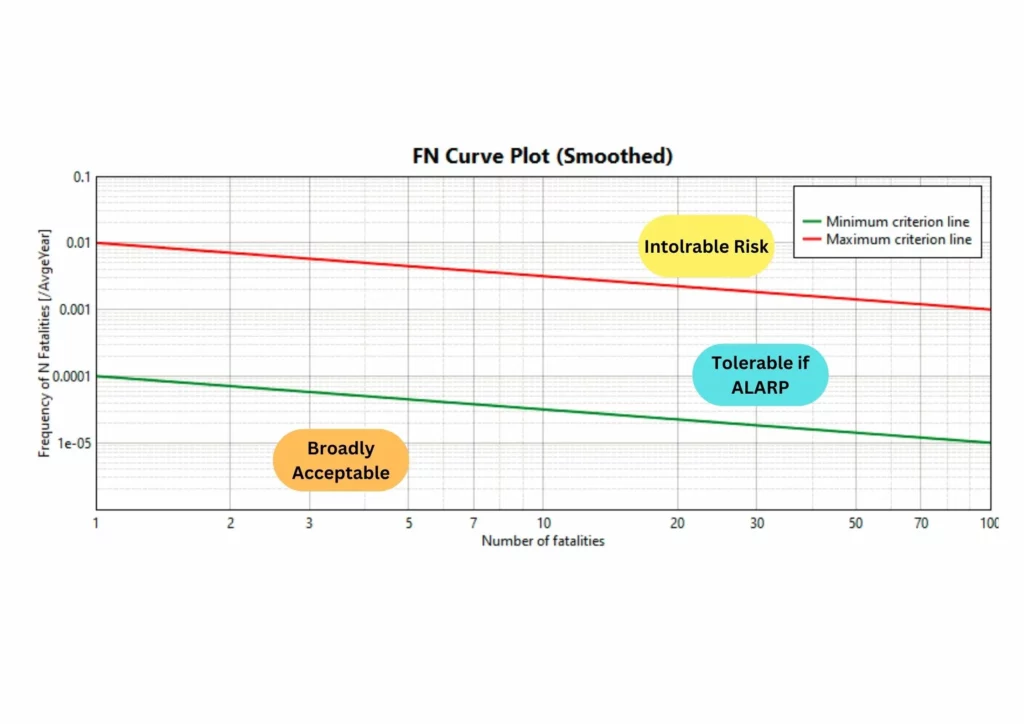

- Estimating risk levels and assessing their tolerability

- Identifying main contributors to risk

- Demonstrating acceptability of risks to regulators and the workforce

- Evaluating risk reduction measures to determine effectiveness in reducing risks

- Identifying safety and environmental critical equipment and procedures

- Providing a basis for current higher cognitive process on safety and operational problems

- Comparing different design options

What will QRA assist you to know?

The most obvious service of a QRA are the 2 ingredients of risk: consequence and probability. For each accident situation known, there’ll be a selected hazard zone (as outlined by the hazard endpoints) and a corresponding chance of incidence. As separate items, the consequence modeling results are typically a lot of helpful than the chance values.

A QRA creates a large amount of result data, allowing for detailed comparison of the effects of hole size(s), climate, and a variety of other variables. Though it is rarely stated explicitly, every unique accident outcome has an associated risk of occurrence. Individual risk levels are the most common and often most useful item a QRA provides.

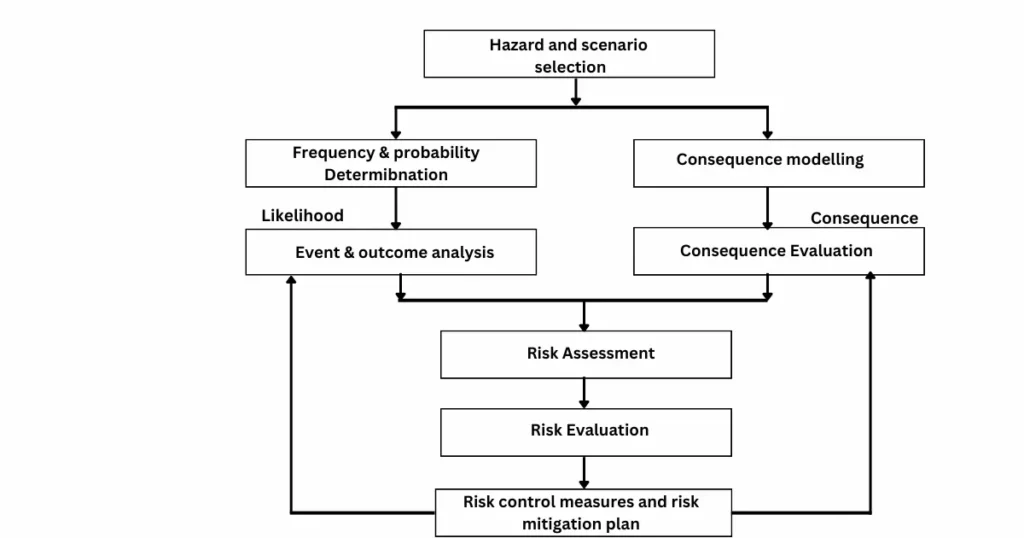

QRA Approach / Methodology

A Typical QRA process includes:

- Hazard identification: Identifying all of the potential hazards that could lead to an accident.

- Event scenario development: Developing a set of scenarios that describe how each hazard could lead to an accident.

- Frequency analysis: Estimating the probability of each event scenario occurring.

- Consequence analysis: Estimating the consequences of each event scenario, in terms of loss of life, environmental damage, and financial loss.

- Risk estimation: Multiplying the probability of each event scenario by the consequences of that scenario to estimate the overall risk.

- Risk evaluation: Comparing the estimated risks to acceptable risk criteria to determine whether the risks are acceptable or need to be reduced.

- Risk reduction measures: If the risks are not acceptable, then risk reduction measures need to be identified and implemented.

Key Benefits on Conducting QRA

- Provides a Systematic and rigorous approach to risk assessment.

- Assess the risks associated with a wide range of processes and systems.

- Identify the most significant risks.

- It can be used to assess the effectiveness of risk reduction measures.

- It can help to prioritize resources.

- It can help to make informed decisions about safety and investment.

Inputs Required (not an exhaustive list)

- Latest Piping and Instrumentation Diagrams (P&IDs)

- Operating Philosophy and Process Conditions/ Operating Parameters

- Population Details (Location and Number)

- Site Meteorology & etc.

- Latest Scaled Layout/ Plot set up

The study will comprise of a number of distinct but interrelated tasks as follows:

- Site visits; ( optional- subject to project case)

- Data collection and review of relevant documents for the project;

- Identification of potential hazardous events;

- Development of the QRA methodology and assumptions report;

- Risk evaluation and integration;

- Consequence assessment including development of incident scenarios using Event Tree Analysis (ETA);

- Failure frequency analysis;

- ALARP demonstration;

- Provision of Risk Reduction Measures (RRMs); and

- Preparation of QRA report for project scope.

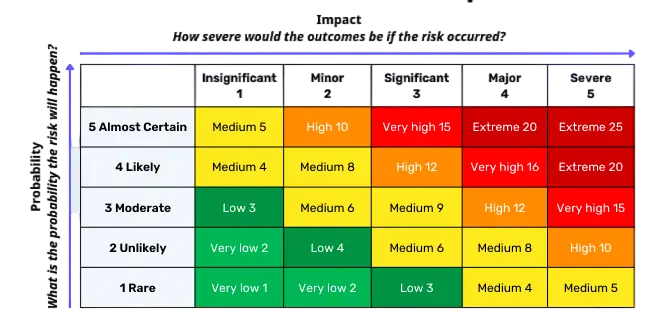

Risk Assessment Matrix

- In risk assessment matrix, you must first identify the hazards you face. Once the risks have been identified, estimate the likelihood and impact of each risk. For both likelihood and impact, a scale of 1 to 5 can be used, with 1 being the lowest and 5 being the highest.

- After determining the likelihood and impact of each risk, plot the hazards on the risk assessment matrix. The hazards that are most likely to occur and have the greatest impact should be placed in the matrix’s upper right corner. These are the risks you should prioritize in order to mitigate them.

Deliverable

- QRA Assumption Register/Methodology Report

- QRA Study Report

iFluids Engineering expert team having sound experience in completing Qualitative Risk Assessments (QRAs), which is a structured approach to identifying and understanding the risk associated with hazardous activities such as the operation of the plant / operation facility

Watch the training video ‘Fundamentals of Risk Analysis’ on iFluids Engineering YouTube channel Click here.