Value Engineering is a systematic approach and effort to analyze the functions of systems, equipment, facilities, services and supplies for the purpose of achieving the essential functions at lowest life cycle cost, consistent with required performance, reliability, quality and HSE.

Why Value Engineering Study

- The method of study is to improve the competitiveness and it is aimed to satisfy the end user needs by means of the modification in specific work procedure which will be functional and economical.

- Value engineering will identify the important activities which is necessary for the process to develop a product or service. The most economical way to permit the effective identification of process cost which shall not contribute to ensure the process quality.

- Value analysis can make an existing process profitable or optimize the effectiveness and the profitability of a process at the time of its design.

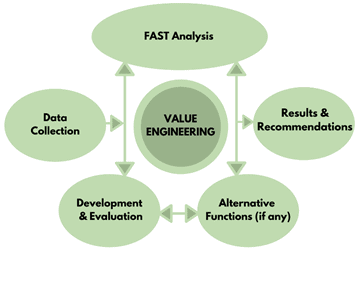

Value Engineering Study Methodology

The value engineering methodology will be applied wherever cost and/or performance improvement is desired for a particular process of developing a product / service.

Workshop & Preparation

Value engineering will be conducted in a work shop with the team of engineers and representatives who involved in that particular project. The study chairman will prepare presentation with required details of project scope, features & characteristics, process operation, VE procedures.

Information Phase

Project basis, features and clear overview of the project facility shall be considered before compiling the facts related to costs and schedule to conduct the workshop. The Major project risk shall be listed out as an information phase shall share and explore all possible risk pertaining to the project scope.

This project risk information includes all the risks involved with the engineering & procurement and delivery of the equipment. Also the needs of modification in the existing system will be listed which are related to any kind of risk.

Function Analysis Phase

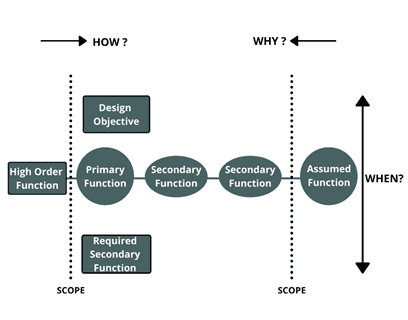

In this phase project function will be identified and defined in detail. Expanding the function list using active verbs that express what the item does and nouns that express the measurable object of the verb. Build a function model using Function Analysis System Technique (FAST) to determine secondary and supporting functions.

The important activities in the aspect of Engineering, Procurement, and Construction will be identified using the function analysis in the aspect of cost and scheduling requirements to meet the project delivery with the complete quality and HSE.

Creativity Phase

The objective of this phase is to develop a large quantity of ideas for performing each function selected for study. Normally diverse group of technical / commercial experts through brainstorming approach, are engaged in generating ideas through non-critical discussion.

Evaluation & Development Phase

The objective for this phase is to gather and analyses data concerning ideas which generated in the Creativity phase. The few feasible ideas will be selected for development into specific value improvement recommendation. This ideas will tend to further discussion in various factors which impact on cost and schedule for the project.

Recommendation & Results

The VE study report summarizing the below;

- Original Design

- Proposed changes

- Advantages & disadvantages of the proposed design

- Discussion Notes

- Life cycle costing compared to original design

- Function analysis sheets

- FAST Graphic presentation

With the final FAST diagram of the project, the team will spend a considerable time for developing and working out ideas for value improvement. Final outcome of the discussions and deliberations will be presented to all representative of the company and engineers involved in that project.