Make-Up Gas Compressors (MUG 75-K-02 A/B Only) System comprises of 3 Stage [4 Cylinders] Reciprocating Compressor Driven by Electric motor, with Suction & Discharge Volume bottles, Inter-Stage coolers and has integrated Lube oil system. Compressor C has been provided with Spill-Back provision for all the 3 Stages, whereas A & B have been provided with Spill-Back arrangement only for the last (3rd) stage. Compressors A & B Capacity enhancement by 10 % has been already implemented. As a result, Motor margin has reduced from 10 % to 5 %. Study for Make-Up Gas Compressor (MUG 75-K-02 A/B Only) Operation with Nitrogen as Medium for IOCL Panipat Refinery Project is required in order to meet the following Objectives:

- Nitrogen is used during Start-up & Shut down of the Plant to provide services like Purging, Heating & Inertising of the plant and equipment, as necessary.

- Compressors MUG 75-K-02 A & B need to operate with Nitrogen (75% of design capacity), for up to 36 hours duration with maximum discharge temperature of less than 150°C.

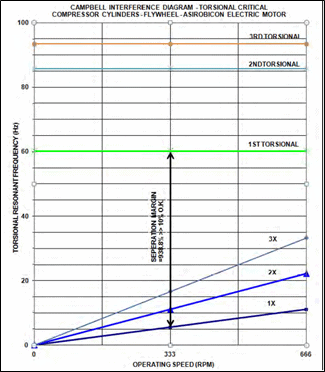

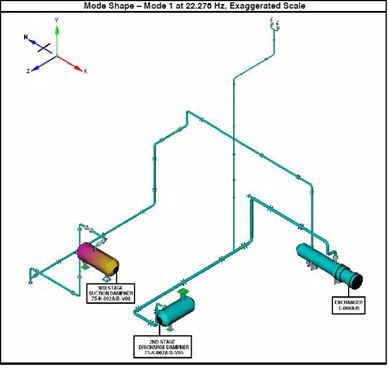

The scope of work includes adequacy checking for nitrogen run in view of valve temperature, flow/capacity, load, motor load, damper volumes, cooling water consumption, LO consumption, safety valves parameters, etc. various analysis includes – Acoustical simulation/ Thermodynamic analysis/ pulsation study/ Piping System Study/ Torsional analysis and Tangential force calculation with required moment of inertia.

- Acoustical simulation study, Thermodyamic analysis & Pulsation study as per design approach – II of API 618

- Torsional Analysis of the Compressor

- Tangential Force calculation & Moment of Inertia

- Piping System Study

- Rod Load Calculation & Diagrams