What is a RAM analysis ?

Reliability, Availability and Maintainability (RAM) study is a structured and quantitative approach implemented for asset optimization and work on the Monte-Carlo principle to significantly lower project costs. Maros is a cost-worthy and basic-level RAM Study Software for reliability engineering studies and reliability modelling to constitute real life scenarios, allowing us to evaluate and enhance production efficiency.

For a RAM Study in Oil and Gas Industry. The following points are considered:

- Evaluation of equipment reliability and redundancy

- Maintenance and mobilization strategy

- Failure rate

- System productivity

- System assessment

Common Issues faced while conducting RAM Study:

- Process/System not meeting the production targets

- Excess cost for achieving the production efficiency

- Unavailability of cost – effective maintenance plan

- Redundant equipment

- Over-design of the system

- Spare parts management for maintenance

What is RAM Modelling?

The objective of the RAM modeling and simulation is to highlight all possible causes of production losses and suggest the best system alternatives. It is a probabilistic approach and work on the Monte-Carlo principle. Thus, the RAM study is a tool for decision-making and optimizing the system by altering specific parameters in the design or it’s logistic to achieve maximum cost-efficiency.

In short the RAM modelling for a given system is performed in following steps:

- Functional Analysis

- Determination of functional diagrams

- Cause and Effect Analysis

- Selection of Quantitative data

- Selection of reliability data

- Plant data, OREDA data etc.

- Selection of operational data

- Basis of design/Philosophies

- Selection of reliability data

- Assessment of production availability

- Building of Reliability block diagram (RBD)

- Maintenance strategies-operational philosophies

- Production availability calculation

- Modelling and Simulation

- Analysis

- Conclusion and recommendation

- Building of Reliability block diagram (RBD)

Difference between maintainability and availability

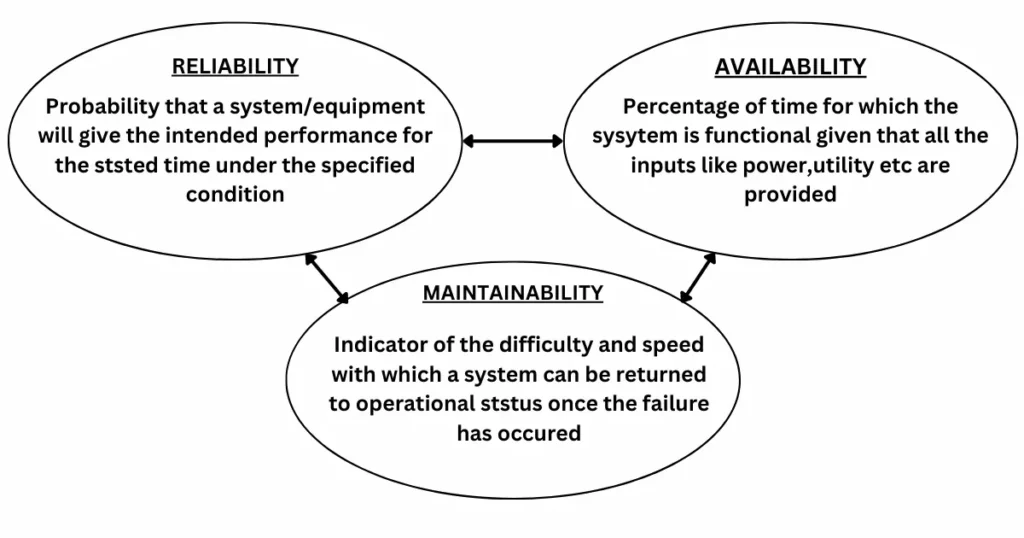

The above figure explains the relationship between Reliability (R), Availability (A) and Maintainability (M) and their definition. Maintainability is the function of difficulty and speed where the system remains functional given the occurrences of Failures. Whereas Availability is the function of Time with all inputs provided so that the system remains functional.

From the above figure and the definition, it is clear that a system will perform optimal when these factors are considered into the design and operation of the system. Hence a proper RAM analysis will result in achieving maximum system ability as per its design. As a result a better decision for productivity, service utilization, maintenance and functioning of equipment is implemented.

Why is RAM so important for calculating and Analyzing?

The RAM study and analysis is generally performed during the FEED stage of the project. However, it can be reviewed and updated as the complexity of project increases with the progress. But this update of the system during the later stage should not impact the project cost.

RAM risk management is performed to evaluate the causes of loss of operational availability or issues that may limit the production throughput and suggest improvement.

The benefits of Calculating and Analyzing in a RAM Studies include:

- Better management of maintenance and spare parts, leading to increase/maintain the production levels;

- Advance contingency plans for any unscheduled or scheduled outage;

- Investment optimization by highlighting the redundancy;

- Accurate prediction of the equipment life-cycle;

- Identification of the critical equipment for the production

What is RAM in risk assessment?

Risk Assessment Matrix (RAM) is a instrument to classify and evaluate the risks, and discuss what changes required to be made so that the risk is as low as possible (ALARP).

To make sure that risk is governed in a organized and logical way is a essential slice of a safety management system. Justifying risk in this way can help better allocation of resources and ensure that acceptable barriers are put in place to ward off incidents.

Applying RAM appropriately and routinely is a common way to communicate and plan for HSE improvement. RAM can help Engineers better acknowledge their personal role in managing the HSE risk in their part of responsibility, and can help them come to a good perception of their role in manifesting risks managed to ALARP level.

Method to use RAM in risk assessment:

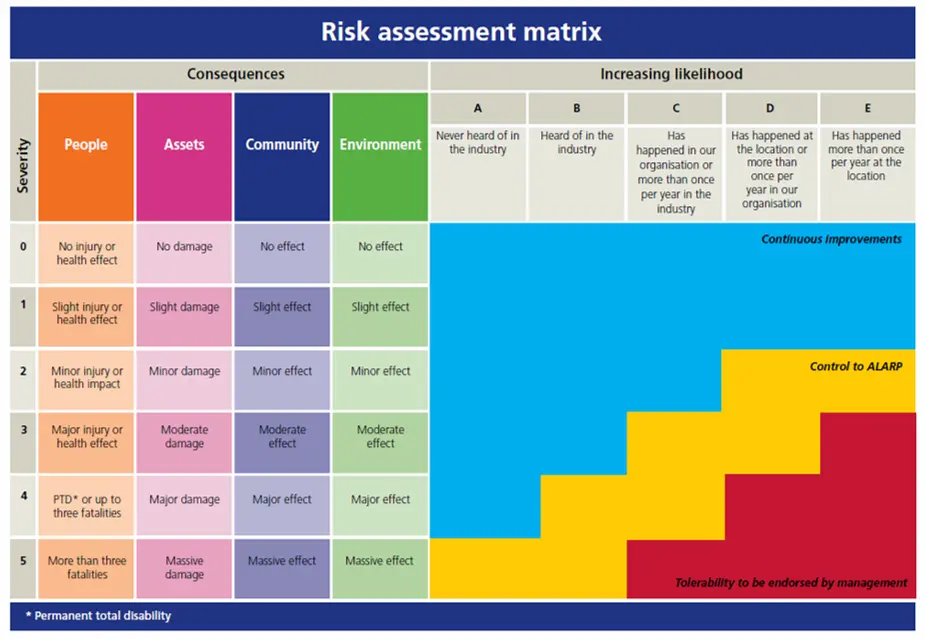

Apply the RAM correctly and regularly as a common way to communicate and plan for HSE improvement. An Example of Ram Risk Assessment Matrix is shown below.

As a Batch exercise, consider the possible events that would occur and plot those events on the RAM based on its severity and likelihood of occurring. Observe how the risk of the event happening can be minimized through changing how the work occurs or fabricating in additional safeguards.

Evaluating the risk of a specific scenario should be done in chronological order, i.e. first the possible outcomes are guessed and only then the possibility of such events happening are assigned. (A scale of outcomes from 0 to 5 is used to stipulate escalating severity). After evaluating the outcomes, the possibility on the horizontal axis is guessed on the scope of historical confirmation or experience that such outcomes occurred earlier.

Make sure that the Risk Assessment entails people in all disciplines who are involved in the tasks being discussed as they will understand the issue and know which response will work. People responsible for planning activities (i.e Managers and Supervisors) should be included for the changes to happen.

RAM formula

Reliability

Reliability is the potential of a system to carry out its activity. Reliability assessment can help in guessing the chances of a system to perform its functions within a definite period under explicit conditions. The reliability function is represented as R(t) of the system when used for t units of time. The probability of the system functions properly at usage [0, t]. Calculation of the reliability value using an exponential equation is shown below.

R(t)=e-λt

Where,

R = reliability value from 0-1,

λ = failure rate, where λ=p/n

p=amount of Data that is out of Scope

n=amount of Data

t = time.

Availability

Availability is the potential of a system to carry out its activities with various features of reliability, mixture, support. Availability changes with time. Calculation of Availability value using an exponential equation is shown below.

A(t)=(r/λ+r ) +(λ/λ+r) e-(λ+r)t

Where,

A = Availability of a system to carry out its activity,

r = Rate of repair,

λ = Failure rate,

Maintainability

Maintainability is the capability of a damaged system to be repaired to its original reliability within a definite time, in line with pre-established procedures. Maintainability has a different formulas based on the data. Calculation of Maintainability value using an exponential equation is shown below.

M(t)=1-e-rt

Where,

M = The ability of a damaged system to be repaired,

r = The rate of repair. Where r=1/MTTR

MTTR= Mean Time To Repair