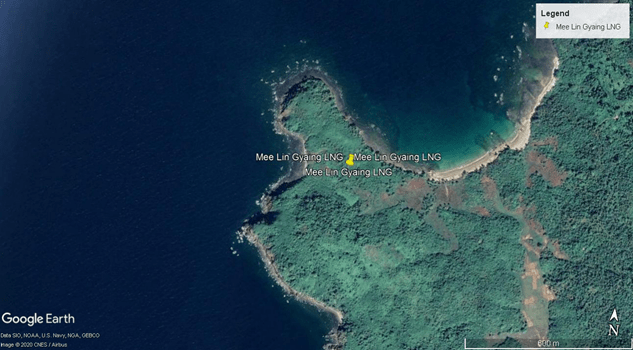

The objective of this QRA and FHA study is to quantify and assess risk from process hazards associated with Mee Lin Gyaing LNG Terminal. The geographic coordinate of the proposed project is 17° 15’58.49″ N, 94° 29’17.37″ E. The proposed facility is a LNG receiving terminal which receives the product through LNG carrier arriving at the jetty. The terminal consists of two LNG storage tanks, each of 16000m3 capacity, BOG compressor, low & high pressure pumps, an open rack vaporiser and the subsidiary equipment and vessels as required. The LNG from the terminal is used as the fuel source to the power plant at the immediate vicinity.

The assessment was be based on the hazards that may occur during the operations of the project according to the information available. The scope of work was limited to the different components associated with the proposed facility only. Any other facilities that are not part of the proposed Complex operations were not included as part of this study.

The following facilities were covered under the QRA study for the Project:

- QRA on impounding basins in this project.

- PSV on LNG tank discharge and fire analysis

- PSV on LNG vaporizer discharge and fire analysis

- Flare discharge analysis

- Other on-site vent devices discharge analysis

The process description of the facility is as below

After the LNG carrier arrives at the jetty, LNG is pressurized by the unloading pumps in the LNG carrier, and enters the LNG storage tank in terminal through LNG unloading arms and unloading header.

During the unloading operation, massive BOG is produced due to the heat transfer and the replacement of vapor space in the LNG storage tanks. Part of BOG will return to the LNG carrier through gas return pipelines and the vapor return arm to balance the pressure in the LNG carrier. The other will be pressurized by BOG compressor and sent to the power station with the natural gas, which has been pressurized by high-pressure pumps and vaporized by ORV.

During the non-unloading operation, all cryogenic liquid pipelines should remain cold through the LNG cycle when not in use, especially for the unloading header. LNG is circulated through the unloading pipeline with the minimum flow through a circulating pipeline from the low-pressure send-out header to keep the LNG unloading pipeline in cold standby status. The circulating LNG returns to the LNG storage tanks. Through the bypass of the top and bottom feed valves through the unloading header.

Under normal operation, the absolute pressure of the LNG storage tank is controlled by the BOG compressors. When a large amount of BOG is generated and the compressors cannot handle it, the excess BOG will be discharged to the flare system through the control valve, which is the first level of overpressure protection of the storage tank; the safety relief valves on the LNG tanks are the second level overpressure protection of the storage tank, and the overpressure gas is directly discharged to the atmosphere.

ORVs are adopted to vaporize LNG in this LNG terminal; Seawater is adopted as the heat medium and sent to the ORVs for heat exchange with LNG. The vaporized natural gas is incorporated into NG send-out header, then transport to the power plant through the metering station.