EPINOX conducted Industrial hygiene study at BPCL, Kochi Refinery to evaluate occupational exposures to air pollutants and physical hazards at their facility located in Kochi.

SCOPE OF WORK

The scope of this work includes assessment of air contaminants such as sulphur dioxide, nitrogen dioxide, total volatile organic compounds (VOC), Respirable Aerosol Mass. The above said exposure assessments were conducted in the places where high levels of emissions are suspected related to the operations inside the plant. In additional to the monitoring of air contaminants, Heat Stress, Vibration and Noise exposure were also monitored..

The results of the exposure were assessed in compliance with the Permissible Limits of Exposure (PLEs) prescribed by The Factories Act, 1948, in conjunction with the Kerala Factories Rules, 1950 and Threshold Limit Values (TLVs) recommended by the American Conference of Governmental Industrial Hygienists (ACGIH), USA.

NOISE STUDY METHODOLOGY INCLUDES

- Evaluation of potential personal exposure to workplace Hazards.

- Walk around survey identified the potential areas within Refinery

- A walk-around survey of the area/facility was carried out and identified the health hazards such as heat, noise and vibration.

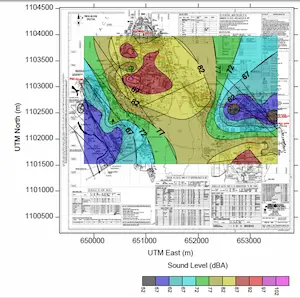

Noise surveys were undertaken in areas where exposure to noise in excess of the adopted limit is suspected. As a general rule, for 90 dB(A) this may be assumed to be the case if a person has to shout in order to be understood at a distance of one metre. In workplaces where the noise levels are reasonably constant the measured level more or less reflects the individual noise dose over a working day. However, in areas where the noise levels fluctuate widely, such as in a workshop, measurements should be carried out over full shifts to establish the personal noise doses associated with each job. The noise data should be assessed in terms of the adopted limit.

Considerable changes in the noise environment may be caused hy factors such as the ageing of machinery, the introduction of new machinery and the alteration of operating practices. Therefore the measurements should be repeated periodically following the initial evaluation.

CONCLUSION OF THE STUDY

It has been found that predominantly the heaters and compressors which were recently installed as per the IREP program were below the equipment level noise level guideline of 85 dBA. Certain areas, had a higher noise exposure to the personnel and the areas where exposure limit crosses 90 dBA shall be marked as restricted areas and personnel working there shall be equipped with sufficient PPE to protect the ears.

Areas such as Utility, compressor – Refinery Area have noise level above 90 dBA and UB 8 Top platform had noise exposure above 100 dBA. The coke cutting platform also experience a high noise area.