What is Hazardous Area Classification?

Hazardous Area Classification (HAC) study is done to evaluate and assess the Plant area based on the presence of Flammable material within the facility. HAC study provides details of Hazardous and Non-hazardous areas in a facility. It explains the possibilities of occurrence of hazardous events such as Fire and Explosion within the facility. Two systems are employed to carry out the study, namely Class or Division system and Zone system.

Areas that constitute Installations of Gas Wells and Gas Processing Plants, oil rigs, process refinery, chemical producing facility, flammable liquid storage facility, fuel transportation facility, Fuel station, Paint Manufacturing Facility, Paper producing Facility are examples of Hazardous Area.

What is considered a Hazardous location?

An area in which the atmosphere holds sufficient quantity of flammable gases, dusts or vapors, and provides a possibility for fire or explosion to occur is considered as a Hazardous Location.

What is Hazardous and Non-Hazardous area?

An Area in which an explosive atmosphere is present in enough quantities and requires precaution measures for fabrication, fitting and use of equipment is called Hazardous Area.

An Area in which an explosive atmosphere is not present and does not require precaution measures for fabrication, fitting and use of equipment is called Non-Hazardous Area.

Where to do Hazardous Area Classification?

- Oil and Gas drilling in Onshore and Offshore Facilities

- Oil and Gas Manufacturing and Processing Facilities

- Refineries

- Petrochemical and Fertilizer industries

- Gas pipelines and Centers

- Terminals, Re-fuelling and Petrol stations

What are Hazard Classifications?

- Hazardous Area Classification is broadly classified into 3 Categories.

- Health Hazards,

- Physical Hazards

- Environmental Hazards

Why do we need Hazardous Area Classification?

- The objective of Hazardous Area Classification is to ensure proper selection and installation of equipment to prevent an explosion and also to avoid the presence of Ignition source such as Electrical apparatus in the Hazardous areas. For Instance If an electrical equipment is present in an area where there is a possibility of continuous or intermittent presence of Flammable liquid/vapour or Combustible dust leading to fire and Explosion, then those areas are easily identified and categorized by this study.

- To ensure Safe operation of plant and safety of personnel during Design and Commissioning stage.

How to do Hazardous Area classification?

Hazardous area classification has four major steps. They are,

- Determination of type of hazard such as combustible gas, combustible dust and fibers that is present in the Facility

- Identification of specific group for the hazardous substance involved.

- Determination of degree of the classification.

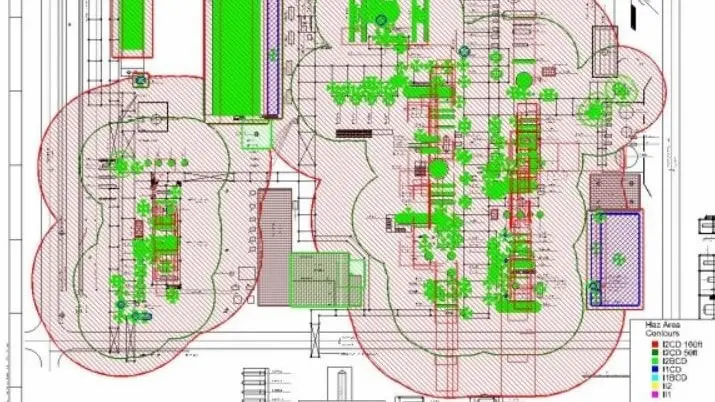

- Determination of the extent of the classified zones and locations in the facility.

Report Output

Hazardous Area Classification Study report helps to identify potentially hazardous and explosive area, determination of extent of hazardous zone and recommends locations for installing special equipment within different zones. As HAC Risk Assessment the report provides design requirements and guidelines for selecting and identifying location of hazardous equipment’s in oil & gas / petrochemical / other industries.

Significance of Hazardous Area Classification study

The following are the five main objective of HAC in a Process plant,

- To eliminate fatality and likelihood due to fire and explosion caused by Flammable material atmosphere occurring near the source of ignition.

- To eliminate the presence of ignition source around the Hazardous area.

- To identify the Hazardous area in the facilities.

- To reduce the Overall risk associated with the facility during design and installation itself.

- To prepare operating and safety procedure for safe operation of plant and persons.

Different types of Hazardous Area Zones

In most of the Installations the risk depends on the duration of hazards such as Gas, Vapor, Dust or Fiber present in the surrounding. In order to catalogue these dangers an Installation is segregated into risk areas based upon the duration of hazards present. These risk areas are referred as Hazardous Area Zones.

| GAS/VAPOUR | DUST | HAZARDOUS ZONE ATTRIBUTES |

| ZONE 0 | ZONE 20 | A hazardous condition is likely to be present and may exist for long periods of time or even continuously. |

| ZONE 0 | ZONE 21 | A hazardous condition is possible but unlikely to exist for long periods of time. |

| ZONE 0 | ZONE 22 | A hazardous condition is not likely to exist during normal operation for short span of time. |

HAC Standards

- International – IEC 60 079 series

- European – CENELEC 60 079 series

- Russia : Gost R 51330-X-99 series

- API RP 505