What is Flow Assurance Study?

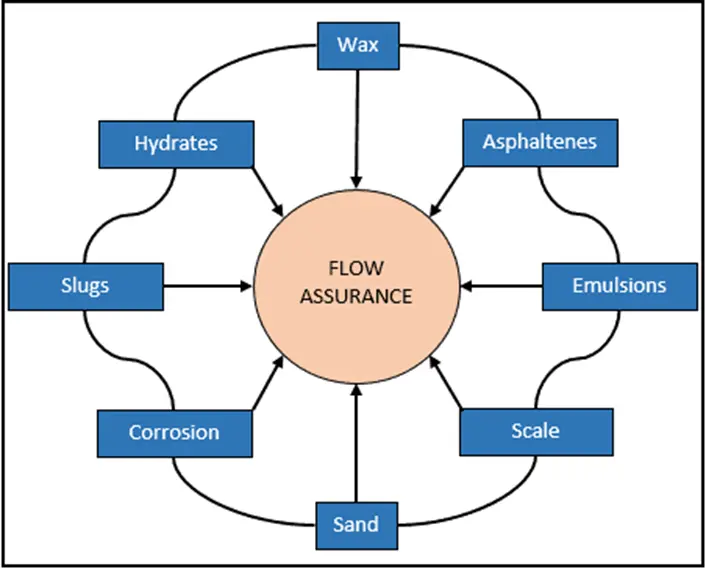

Flow assurance study involves a cost-effective approach to produce and transport fluids from the reservoir to a processing facility. During production and transportation of crude oil, fluid properties and operating conditions must be monitored. The task here is to forbid the development and accumulation of undesirable solids (e.g. scales, sand, emulsions, wax, hydrates, asphaltenes & slugging) with the desired pressure and temperature

What are the Flow Assurance Study Objectives?

The Objective of Flow Assurance Study is to inexpensively enhance the transportation of fluids from the Reservoir to the Processing Facility

What are the types of Flow Assurance?

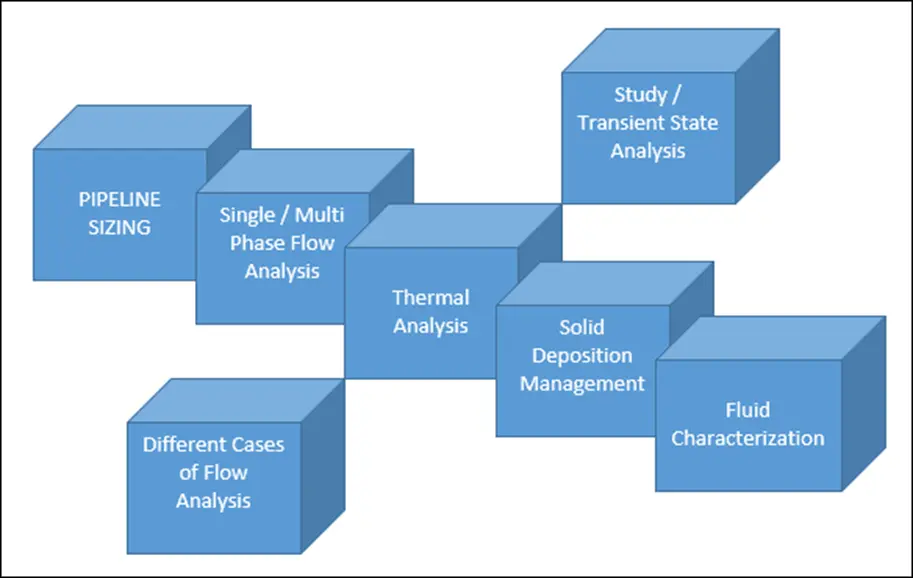

The flow assurance study will cover the following,

- Steady state Simulation

- Transient state simulation

Steady state Simulation

The following outputs shall be established using Steady Sate Simulation,

- The size and pressure rating for the required pipeline.

- Pressure and temperature profiles to determine the design conditions.

- Max operating pressure/temperature and min. operating pressure/temperature for all platforms and pipelines

- Critical transport scenarios from erosional velocity point of view.

- Fluid velocity profiles.

- Fluid density profiles.

- Actual velocity vs erosional velocity

- Liquid Hold-Up & liquid inventory

- Sensitivity simulation analysis

Transient state simulation

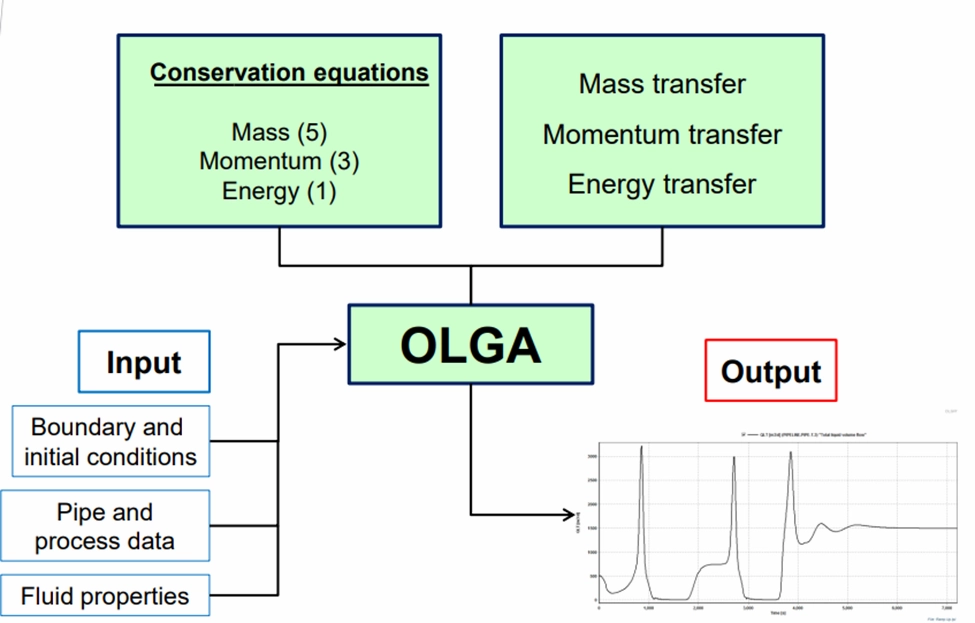

The transient hydraulic analysis shall be carried out for the gas pipeline, using OLGA (latest version) software. Following cases shall be considered.

- Unplanned shutdown and cooldown

- Blowdown/depressurization

- Pressurization study aimed at selecting ESD settings, PST and PZV settings

How do you calculate Flow Rate?

Flow Assurance Study For Pipeline

Flow Assurance study for Pipeline involves the following Steps.

- Step 1: Input Data Collection

- Step 2: Discussion with client to determine flow assurance cases and analyses to examine; prioritize flow assurance analyses. Agree on scenarios, simulations, and studies to be conducted

- Step 3: PVT Analysis

- Step 4: OLGA model updating to perform Flow Assurance steady state analysis/Flow Assurance transient analysis.

- Step 5: Flow Assurance analysis for the proposed flow line,

- Step 6: Draft report preparation

- Step 7: Client review and incorporation of Client comments

- Step 8: Preparation Final Flow Assurance Study Report

Benefits of Flow Assurance Study

Flow assurance study shall ensure the uninterrupted flow throughout the pipe network in multi-phase fluid (oil, gas & other components) in upstream, midstream & downstream oil & gas industry. The study will provide the detailed mitigation measures to manage the risk of processing the formation and deposition fluids in pipeline with appropriate flow assurance simulation software.

Flow Assurance study includes some of the following

Wax Formation

If there is a potential for wax appearance below temperature range (cloud point of the reservoir fluid) in upstream oil field, wax deposition may take place in the production flow line and associated processing facilities. To avoid wax deposition in process the temperature shall be maintained above the wax appearing temperature.

Hydrate Prevention

The presence of free water in oil & gas production pipelines aids the formation of hydrates under certain pressure and temperature conditions. Hydrates formation will partially or fully block the fluid flow in pipes, which results in backpressure on the wellhead and reduced well production.

Hydrate formation temperatures are estimated at various stages of processing. The fluid temperature during various stages of processing are maintained above hydrate formation temperature. For that various heater and the heat tracing for the process lines to be provided based on the flow assurance study report.

Some of potential areas has been mentioned below in upstream oil & gas facility where hydrate formation may occur.

- Process flow lines during shut-downs

- Riser depressurization

- Facilities downstream of choke-valve

Sand removal

To achieve flow assurance and manage integrity of the system, sand monitoring and removal facilities are to be provided. The early warning of sand production from a well or production stream can be monitored using a sand detector strapped on to the inlet flow lines. Sand sampling facility is provided to prevent sand carryover.

Scales

Scale formation may occur in the flow line and due to mixing of water injected to well to maintain the pressure in reservoir. The appropriate scale inhibitor shall be recommended through flow assurance study which will ensure the flow rate assured in pipelines.