Chennai Petroleum Corporation Limited (CPCL), one of the leading group companies of Indian Oil’s, was conceived in 1960s as a 2.5 million metric tons per annum (MMTPA) refinery designed to produce fuels and lubes base stock. At CPCL, the past five decades have an eventful, growth-oriented phase as the CPCL family built the organization to reach the present stature of 10.5 MMTPA capacity.

The scope of the project is:

- To conduct a detailed study of the newly installed Demountable Flare Systems at CPCL, Manali, Chennai to ensure that there are no Odour emissions due to improper combustion or at any metrological conditions.

- To calculate Combustion Efficiency of all flares and to study the gas dispersion pattern for DMF.

Demountable flare stack system installed at CPCL, consists of one Hydrocarbon flare stack for normal flaring, with capacity equal to 2% of peak flaring. Apart from this, there are 3 flare stacks (two operating one standby), each designed for 50% of the peak flare load. Two Acid flare stacks, each equivalent to 100% of the peak flaring were also installed.

The Dispersion pattern & Odour emissions at different weather conditions after flaring was studied, for which the following combustion equation was considered: –

CnH2n+2 + (3n+1)/2 O2 → n CO2 + (n+1) H2O + energy => for HC flares

H2S + 1.5O2 → SO2 + H2O => For ACG flares

NH3 + 1.25O2 → NO + 1.5H2O

From the above reaction, The Odour emissions of SO2 was studied at its OSHA Odour threshold of 1ppm.

The Toxic Gas Dispersion pattern for SO2, NO at their STEL concentrations of 5 & 25 ppm respectively were also studied.

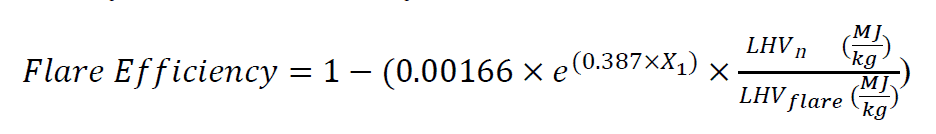

- The Flare efficiencies of each flare were calculated using the following empirical formula: –

From the study, the following results were established: –

- Toxic Dispersion of the Combusted Gas was studied for all the flares under different weather conditions and two Release Directions (Vertical & Horizontal). From the results, no impact of Toxic Emission under any condition was observed.

- Dispersion pattern study for Odour Emission of SO2 at the OT of 1ppm was carried out for 100% combustion case and no impact of odour was observed under any weather and release conditions.

- The Flare Efficiency for all the flares was calculated using the empirical formula and the minimum efficiency was found to be 98.5% for which no odour emission was observed.