Computational Fluid Dynamics based explosion study is a mode of depicting the physical effects and hazards of releases that are typically quantified using 2D or 3D analytical approach based on semi-empirical equations.

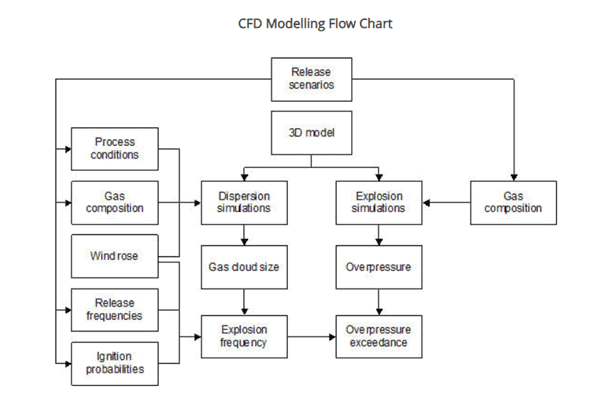

The objective of the study is to have a better understanding of the probable consequence and extent due to an explosion. For this study, the CFD results are directly applied to find the cloud dispersion/size and resulting maximum explosion pressure. This combined with the probabilistic modelling will give a detailed risk picture.

Explosions represent a hazard frequently found in the process industry. It consists of a rapid combustion of clouds producing a fast release of energy and gas expansion. Explosions are complex phenomena, which come from a sudden and rapid release of energy.

This energy is dissipated in the form of heat radiation, acoustic waves, and waves of pressure. Explosions can be characterized depending on their various source of generation such as the liquid at boiling, reactions out of control, and partially confined vapour. The study differs as per the nature of explosion. Few reasons for the same are,

- Low occurrence time scale

- Uncertainty in the pressure wave

- Uncertainty on the energy released

For the above, many simplified models consisting of mathematical correlations with parameters of occurrences under real-world scenarios are available. This kind of available models can reliably represent explosions and determine the profile of overpressure. Among other, the TNT equivalence, TNO Multi–energy and Baker–Strehlow (Used in QRA).

The results of these methods have been used to allocate process units and containment systems. Unfortunately, these models do not consider the effect of obstacles in the explosion. Despite this, these models have been used frequently due to their simplicity.

Computational Fluid Dynamics predicts the possibility of explosion with greater precision accounting for the local environment such as confinement, congestion and blockage issues which makes it a better tool for risk estimation.

Significance of Computational Fluid Dynamics Explosion Study

Computational Fluid Dynamics is a very comprehensive analysis tool, as it can accurately visualize the complex physics more realistically, and the tools have powerful visualization capabilities. Engineers can analyse the performance of a wide range of gas cloud dispersion, fires and vapor cloud explosion configurations in the virtual computer environment without the time, expense, and disruption required to make actual changes onsite. Visualization of 3D videos also improve the understanding of consequences from unwanted gas and liquid releases.

Benefits of 3D and 2D CFD based Explosion study

3D modelling is predominantly used for design purpose and also for process safety applications considering the better picture on the facility provided. 3D models will also attempt a more complete description of the physical and chemical processes involved, including better representation of the geometry and the accuracy of numerical schemes.

However 2D models provide fast calculations due to approximation with empirical relations and are relatively easy to use. Further uses of CFD in process safety are that, CFD has been used to predict gas and vapor dispersion, blast from gas, pool fire and dust explosions. CFD can solve numerous problems of simulation for explosion under various physical scenarios such as,

- An obstructed environment equivalent to a porous.

- A confined environment.

- Venting ducts etc.

Through CFD explosion study, more informed decisions about fire or blast protection requirements can be taken due to its relative accuracy of predicting explosion over pressures even in congested areas accounting for the obstructions, which could otherwise lead to unjustified and unreasonable expenditures.