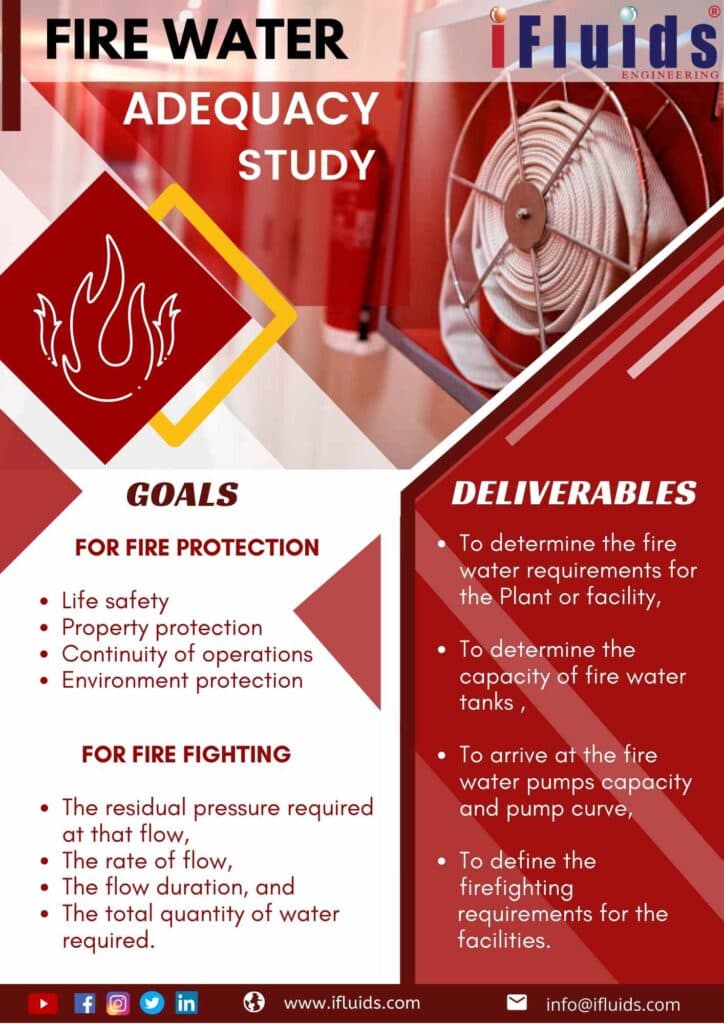

Adequacy study for the firefighting system to satisfy the standard of fire protection to meet the industrial standards for safe operation. Firefighting adequacy includes the study of fire hydrant, sprinkler/spray, foam system, hydraulic study for the fire water network. All the firefighting system will be checked & stabilized based on the international standards and guidelines to ensure providing the safe operation in any industry.

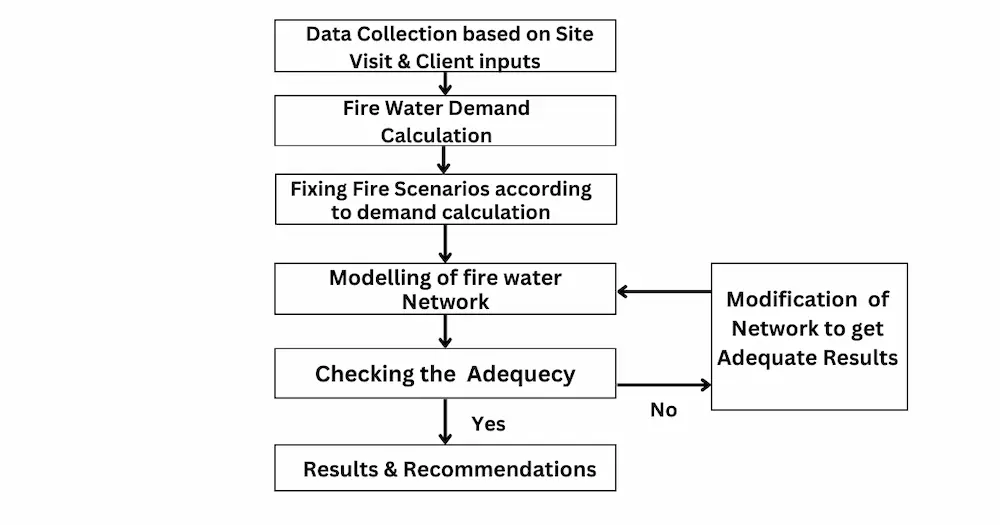

Study Methodology

The adequacy check for existing or proposed firefighting system shall be carried out based on the international standards like Shell DEP, NFPA, BIS, IS and client requirements. The study comprises the following under firefighting adequacy:

- Fire water demand calculation, requirement & its storage

- Hydraulic study for the entire fire water network

- Assessment of existing fire protection system

- Fire water demand calculation, requirement & its storage

- Hydraulic study for the entire fire water network

- Checking of fire water spray / sprinkler, hydrant, monitor, hose reel requirement

- Checking and recommendation for deluge system

- Potable & mobile firefighting equipment requirements

- Foam/water monitor system

- Automatic detection & fire suppression system study

Fire water demand calculation and hydraulic study has been taken as an example and the methodology for the study have been discussed below;

Guidelines & General Practices

- The fixed water spray system shall be provided for all the hydrocarbon tanks irrespective of diameter

- Water flow calculated for exposure protection for all the tanks falling within a radius of (R+30) m from the center of the tank on fire.

- For atmospheric storage tanks containing class B products (fixed roof or floating roof) of diameter larger than 30 m shall be provided with fixed water spray system

- Foam system shall be provided for the floating and fixed roof tanks storing class B products of diameter larger than 18m.

- Hydrants or water monitors shall be located keeping in view the fire hazards at different sections of premises to give most effective coverage.

- At hazardous locations, number of hydrants shall be based on one hydrant or water monitor for every 30 m of external perimeter of process units, storage tank areas, hydrocarbon pumping station/ house, blending station, utilities etc.

- The fire water network shall be laid in closed loops as far as possible to ensure multi-directional flow in the system.

- Isolation valves shall be provided in the network to enable isolation of any section of the network without affecting the flow in the rest.

Fire Water Demand & Hydraulic Study

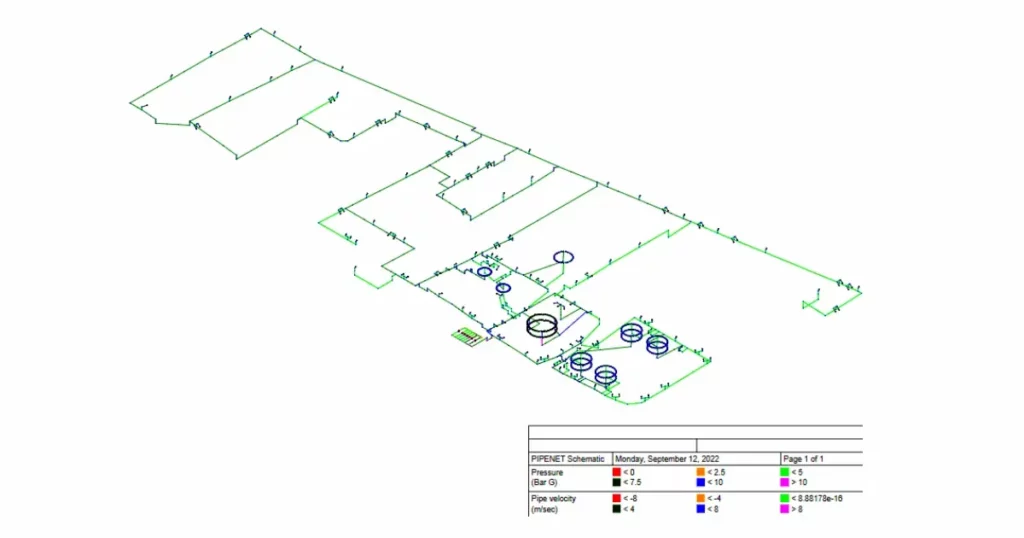

Hydraulic analysis of the existing FW piping network and by calculating the fire water demand to cater for fighting any major fire contingency. The adequacy study can be done for the existing / proposed plant or for any extension of existing plant which needs the below details as inputs,

- Overall layout of the firefighting facility

- Fire zone layout

- P&ID of FW system

- Datasheets

- Specifications

Fire Water Demand Calculation

The layout shall be checked to meet the fire water demand for firefighting in worst case scenario simultaneously in various location as per company guidelines / standards. The most hazardous area will be taken into consideration for the fire water demand calculation. The maximum velocity, design flow rate and pressure shall be checked to meet the maximum requirement of water demand. The hydraulic analysis of network shall be done assuming several combination of flow requirement at different points to give the most realistic way of water requirement in emergency.

The results of the transient analysis of each fire water network system shall be generated and the recommendations will be given accordingly. Fire water demand calculation for Depots and terminals are based on OISD-117 and for petroleum refineries is OISD-116

Modelling of the fire water network involves the following steps:

- Predefining the pumps and nozzles

- Predefining the pipe.

- Selection of Module and pressure drop model (Hazen-Williams is preferred for fire water system)

- Drawing the network based on the given layout.

Firefighting System Report output

The firefighting adequacy check shall be done for any facility to provide observations and recommendations as an output based on the guidelines / standards.

Existing Plant

- All the existing hydrocarbon storage tanks will be accounted for fire water demand calculation.

- Distance between the each hydrant / monitor shall be checked and recommended if not adequate.

- Adequacy check for existing FW pumping system to meet required flow rate and pressure.

- Checking of existing deluge system coverage and recommendations if not adequate.

- Checking of existing specification of spray / sprinkler system, hydrant, fire monitors, fire hoses.

- Checking of existing foam / water monitor control system.

- Checking of existing firefighting philosophy and recommendations.

New Plant

- Recommendation for firefighting system as per international standards.

- Foam / Water demand calculation for the proposed plant.

- Recommendations for new deluge system

- Locating fire hydrant, monitor, hoses, sprinkler / spray system as per standard.

- Hydraulic study for the entire fire water network to meet the required flow rate and pressure in the end of the network.

We are Happy to Help, Kindly Contact Us

iFluids can support you in maintaining a Safe, Reliable Facility