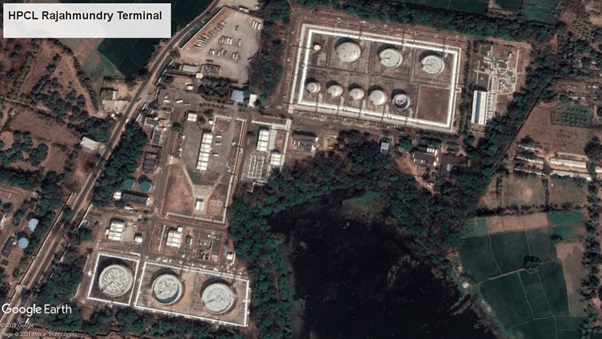

Hindustan Petroleum Corporation Limited (HPCL) Rajahmundry Terminal consists of above ground storage tanks for storing HSD, MS, SKO. Adhering to the norms of OISD, Sprinklers are provided for cooling the tanks in case emergency along with Fire water pump house, Tank truck gantry and VVSPL Pump house.

Adequacy study for the firefighting system is performed to satisfy the standard of fire protection and to meet the industrial standards for safe operation. The sprinkler system, which is a part of the firefighting system is checked & stabilized based on the international standards and guidelines to ensure providing the safe operation in any industry. The existing sprinkler rings are at a distance of 0.9 m from the tank shell.

iFluids Engineering having the subject matter expertise in this field has been entrusted by HPCL to perform the Sprinkler adequacy check for the calculated fire water demand and Sprinkler nozzle pattern adequacy check when the existing ring is at a distance of 0.9 m from tank shell.

The study is carried out as following:

- Fire water & Sprinkler system modelling:

The fire water and sprinkler system in the terminal is modelled in a fluid flow analysis software based on the provided layout and relevant drawing documents.

- Sprinkler Adequacy Calculation:

Sprinkler adequacy calculation is performed using in-house sprinkler calculation spreadsheet. Based on the number of Sprinklers/nozzle in each Tank rink and respective K-factors, the fire water required is calculated and compared to the required fire water demand as per OISD 244 for each tank.

- Firewater system hydraulic analysis

The fire water demand from software model and calculated fire water demand is compared for single fire and two simultaneous fire scenario (with supplementary) with the required pressure, flow and velocity. Orifice diameter is optimized to meet the required fire water demand in the software model.

- Spray nozzle throw pattern analysis:

The tank area coverage is checked by analysis of existing spray nozzle throw pattern for each ring in each tank using computer aided design and drafting software.