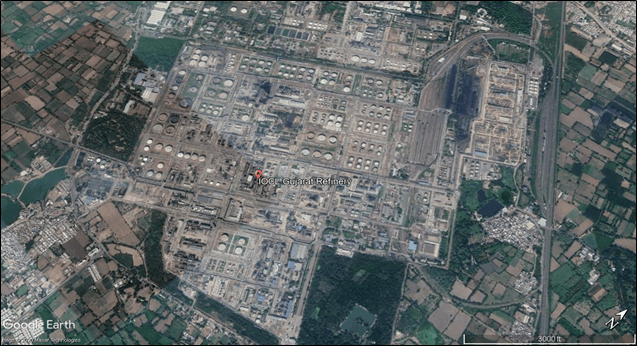

Indian Oil Corporation Limited (IOCL) has one of its largest oil refineries at Koyali (near Vadodara) in Gujarat, Western India. The refinery was commissioned in the year 1965. Indian Oil and its subsidiaries have a dominant share in petroleum products market, national refining capacity and downstream sector pipelines capacity. With a robust workforce, Indian Oil has been helping to satisfy India’s energy demands for over five decades now.

Tank-551,552,553,556 (Capacity – 3000, 3000, 3000, 6000 m3 respectively) are provided for the storage of 110-170 Deg. C cut Naphtha either from AU-I or AU-II alone or from both the units. 30-FR-101 records the flow. For BT mode, Tank-552/553 can receive the BT feed from AU1/AU2, For MS mode, Tank-551/556 can receive MS feed. For combined mode: any of the above four tanks can receive feed from AU-1/AU-2. Before filling up the tank for feeding, ensure that it is free from any water.

Facilities are also provided for receiving slop of Pre-treater and/or Reformer, Light Charge Stock and rundown reformate in these tanks. These facilities are provided for use during any emergency situation and should be kept blinded in normal condition. Reformate stored in these tanks can be pumped out to OM&S using Line no. 45 or general naphtha if required, using pump H-17.

The scope of the project consists of performing Quantitative Risk Assessment for Naphtha Tanks, IOCL Gujarat Refinery.

The study objectives are as follows:

- Identification of hazards and release scenarios

- Assessment of the risk

- Risk Evaluation

- Risk elimination/reduction