A lightning strike is an electrical discharge between the cloud and the earth. It is a natural, unpredictable phenomenon having independent current source. It consists of different components such as lightning current, very high peak current, charges and specific energy with a wave shape of 10/350 µs.

Lightning is a naturally occurring phenomenon that often causes severe damage to life and property. Direct hits may cause structural failure whereas, indirect hits through inductive or capacitive coupling, may affect the reliability and integrity of electrical and electronic equipment within the structure.

Conventional method of lightning protection system consists of lightning masts / rods exposed and placed at the highest levels of structures and connected through downward conductors to a grounding system. A design method is normally used to identify the most suitable locations for the lightning masts / rods, based on the area of protection offered by each one.

The overall objective of the Lightning Protection Assessment Study is to check and ensure that the entire plant area including structures/buildings and tank farms are safe from lightning phenomena. This is to be done based on Lightning Protection Standard OISD-GDN-180 & IEC 62305. Click Here to learn on What is Lightning Protection Study?

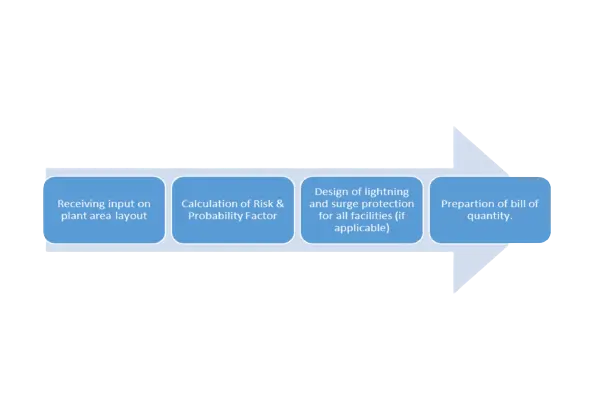

METHODOLOGY

There are different methods of lightning protection systems. Examples of existing methods include geometrical constructions, such as the “Protective Angle Method” and “Rolling Sphere Method” which is based on “Electro geometric” models (EGMs). The Rolling Sphere Method is a simple means of identifying areas of a structure that need protection, considering the possibility of side strikes to the structure. There are different radii of the rolling sphere that correspond to the relevant class of LPS.

This method is suitable for defining zones of protection for all types of structures, particularly those of complex geometry. Rolling Sphere Method recognizes that the attractive effect of the lightning mast / rod is a function of a striking distance which is determined by amplitude of lightning current. This method is considered relatively simple and easy to apply.

The protective angle method is a mathematical simplification of the Rolling Sphere Method. The protective angle (α) is the angle created between the tip of the vertical mast / rod and a line projected down to the surface on which the rod sits. The protective angle differs with varying height of the air mast/ rod and class of LPS. The protective angle afforded by an air rod is determined from IEC 62305-3. The protective angle method is better suited for simple shaped buildings. However, this method is only valid up to a height equal to the rolling sphere radius of the appropriate LPL.

The Rolling Sphere Method is more versatile and can be used in all circumstances. Hence, the method is adopted for the assessing lightning protection in the plant area where numbers of lightning rods are installed in the chimneys and structures.

The plant consists of concrete as well as steel structures. Risk assessment of these structures has been carried out as per IEC 62305-2: 2010.

FACTORS TO BE CONSIDERED TO CARRY OUT LIGHTNING PROTECTION STUDY

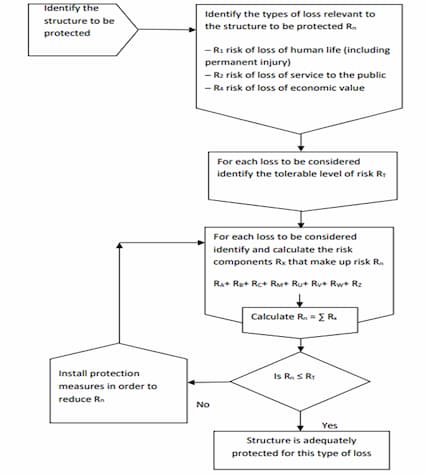

Risk Assessment

The assessment is based on the definitions in IEC62305-2. The result of the assessment defines the level of LPS required.

The first stage of the risk assessment is to identify which of the four types of loss (as identified in IEC 62305-1) the structure and its contents can incur. The aim of the risk assessment is to quantify and if necessary, reduce the relevant primary risks viz.:

- R1- risk of loss of human life (including permanent injury)

- R2 – risk of loss of service to the public

- R3 – risk of loss of cultural heritage **

- R4 – risk of loss of economic value

- ** R3 is not considered in this assessment as deemed to be not relevant for this installation.

All the major structures / buildings in the L plant have been evaluated for risk assessment using the flowchart given in the Figure below:

OUTCOME OF LIGHTNING PROTECTION STUDY

- Risk assessment and recommendations for the tank farm area

- Risk assessment and recommendations for the building & structures

- Risk assessment and recommendations for other plant areas

CASE STUDIES

iFluids Engineering, with our in-house specialized Engineering Team, has carried out several Lightning Protection Assessment Studies. Some key Projects are as follows:

LIGHTNING PROTECTION STUDY FOR HPCL – RAMAGUNDAM DEPOT

Hindustan Petroleum Corporation Limited (HPCL) has a POL Depot at Ramagundam, for the purpose of receipt, storage, and dispatch of petroleum products (POL) such as Motor Spirit (MS), High Speed Diesel (HSD), Bio Diesel and Ethanol.

The HPCL POL Depot are in the Ramagundam Depot with the following areas.

- Land Area – 56.194 Acres

- Structural Area – 11782.37 sqm.

- Green Belt – 52260 sqm.

- Truck Parking Area – 9600 sqm.

The following was the scope of study.

- Review and assess necessity of lightning protection for all the structures / buildings, Tank Farm – I area and Tank Farm – II area

- Review coverage of lightning protection provided by the high mast lighting poles with air terminals.

LIGHTNING PROTECTION STUDY (LPS) AS PER OISD-GDN-180 & IEC 62305 FOR HPCL- VISAKHAPATNAM TERMINAL

Hindustan Petroleum Corporation Limited (HPCL) has a POL Terminal at Visakhapatnam, for the purpose of receipt, storage, and dispatch of petroleum products (POL) such as Motor Spirit (MS), High Speed Diesel (HSD), Bio Diesel, Kerosene, Ethanol, Mineral Turpentine Oil (MTO), Naphthalene and Air Turbine Fuel (ATF).

The HPCL POL Terminal are in the Visakhapatnam Terminal with the following areas.

- Land Area – 75.65 Acres

- Structural Area – 14456.2595 sqm.

- Green Belt – 11.72 Acres

- Truck Parking Area – 11950 sqm.

The following is the scope of this study.

- Review and assess necessity of lightning protection for all the structures/buildings, Tank Farms – I, II, III, IV and V areas

- Review coverage of lightning protection provided by the high mast lighting poles with air terminals.

LIGHTNING PROTECTION STUDY AS PER OISD-GDN-180 & IEC 62305 FOR HPCL- VIJAYAWADA TERMINAL

Hindustan Petroleum Corporation Limited (HPCL) has a POL Terminal at Vijayawada, for the purpose of receipt, storage, and dispatch of petroleum products (POL) such as Motor Spirit (MS), High Speed Diesel (HSD), Bio Diesel, Superior Kerosene Oil (SKO), Aviation Turbine Fuel (ATF) and Ethanol.

The HPCL POL Terminal are in the Vijayawada Terminal with the following areas.

- Structural Area – 31615.855 sqm.

- Solar Plant Area – 11375 sqm.

- Truck Parking Area – 39703.95 sqm.

The following is the scope of this study.

- Review and assess necessity of lightning protection for all the structures/buildings, Tank Farms – I, II, III, IV and V areas.

- Review coverage of lightning protection provided by the high mast lighting poles with air terminals.

LIGHTNING PROTECTION STUDY AND PROVIDING RECOMMENDATION FOR GAPS TO COMPLIANCE THE REQUIREMENTS OF OISD-GDN-180 OF HPCL BENGALURU TERMINAL

Hindustan Petroleum Corporation Limited (HPCL) has a POL Terminal at Bangalore, for the purpose of receipt, storage, and dispatch of petroleum products (POL) such as Motor Spirit (MS), High Speed Diesel (HSD), Bio Diesel, Ethanol and Air Turbine Fuel (ATF).

The HPCL POL Terminal are in the Bangalore Terminal with the following areas.

- Land Area – 35 Acres

- Structural Area – 6540.365 sqm.

The following is the scope of this study.

- Review and assess necessity of lightning protection for all the structures/buildings, Tank Farms – I, II, III and IV areas

- Review coverage of lightning protection provided by the high mast lighting poles with air terminals.

LIGHTNING PROTECTION STUDY AS PER OISD-GDN-180 & IEC 62305 FOR HPCL KADAPA DEPOT

Hindustan Petroleum Corporation Limited (HPCL) has a POL Depot at Kadapa, for the purpose of receipt, storage, and dispatch of petroleum products (POL) such as Motor Spirit (MS), High Speed Diesel (HSD), Bio Diesel, Kerosene and Ethanol.

The HPCL POL Depot are in the Kadapa Depot with the following areas.

- Land Area – 56.194 Acres

- Structural Area – 11782.37 sqm.

- Green Belt – 52260 sqm.

- Truck Parking Area – 9600 sqm.

The following is the scope of this study.

- Review and assess necessity of lightning protection for all the structures/buildings, Tank Farms – I, II and III areas.

- Review coverage of lightning protection provided by the high mast lighting poles with air terminals.