INTRODUCTION

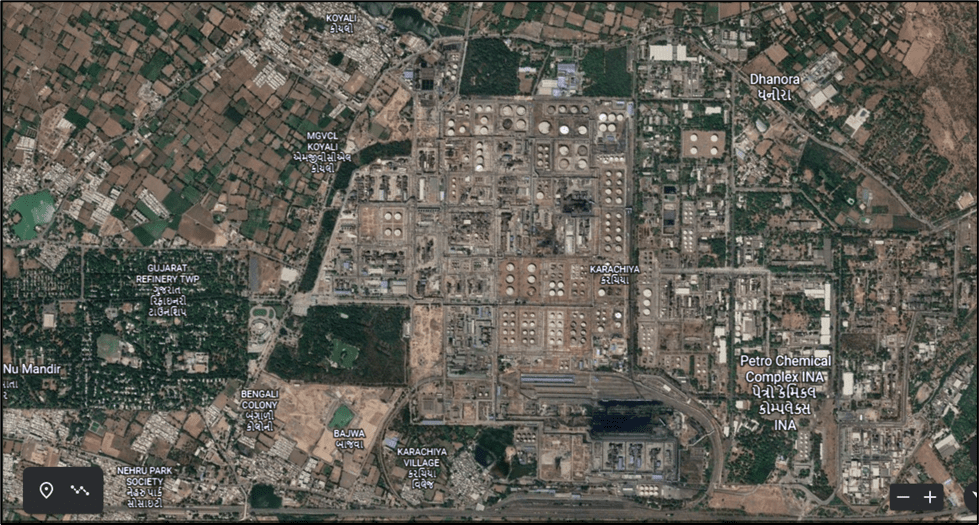

Gujarat Refinery, IOCL’s 3rd largest Refinery, is located at Koyali, Vadodara District in Gujarat, Western India. It is currently under production expansion, projected upto 18 million tonnes per year. M/s. Indian Oil Corporation Ltd. (IOCL) had floated a tender to conduct the Hazard and Operability Study (HAZOP) for the Gujarat Refinery in line with OISD guidelines which has been awarded to IFLUIDS Engineering.

HAZOP Study Objective

The HAZOP study objective is to identify hazard and operability problems, to reduce the likelihood and severity of an incident in the process units, utilities & offsite facilities in the Indian Oil Corporation Ltd. (IOCL) that pose a serious impact to the plant, personnel, properties and environment.

Methodology of HAZOP

- Node mark-up based on (Stream, Equipment or Package) on the P&ID

- List all the intention & process parameters for that node

- List all deviations and disregard deviations that are not meaningful within the Node

- Brainstorm and list the various causes of deviation and disregard causes that are not credible

- Brainstorm the consequences of the deviation for all the listed credible causes

- Identify Safeguards already provided in the system

- Apply Risk Matrix based on severity & likelihood

- Propose recommendations wherein the safeguards are found inadequate

Scope of work:

HAZOP Study of Gujarat Refinery has been carried out in two phases, such as :

- Phase 1- 41 Process Units

- Phase 2 – Offsite / tank farm

Phase 1 of HAZOP study:

The total number of P&ID’s for 41 process units assessed was approximately 1333 Nos.

Phase 2 of HAZOP Study:

The total number of P&ID’s for offsite / Tank farm assessed was approximately 150 Nos.

Process Units at Gujarat Refinery:

| S. No. | Process Unit | No. of P&ID |

| 1 | AU-04 | 13 |

| 2 | VDU | 11 |

| 3 | VBU | 13 |

| 4 | BBU | 9 |

| 5 | DCU | 182 |

| 6 | VGO-HDT | 117 |

| 7 | ATF MEROX | 32 |

| 8 | COKER LPG MEROX | 33 |

| 9 | FCC LPG MEROX | 24 |

| 10 | MTBE | 22 |

| 11 | AU3 | 22 |

| 12 | HCU | 76 |

| 13 | FPU-2 | 31 |

| 14 | HGU-1 | 15 |

| 15 | FCCU | 54 |

| 16 | FPU-1 | 13 |

| 17 | Nitrogen unit | 18 |

| 18 | AU-1 | 29 |

| 19 | AU-2 | 21 |

| 20 | AU-5 | 27 |

| 21 | CRU | 29 |

| 22 | ISOM | 97 |

| 23 | SRU-3 | 67 |

| 24 | ARU-3 | 36 |

| 25 | SWS-1 | 16 |

| 26 | SWS-2 | 16 |

| 27 | HGU-3 | 46 |

| 28 | DHDT | 41 |

| 29 | DHDS | 64 |

| 30 | HGU-2 | 29 |

| 31 | 008SWS-1 | 5 |

| 32 | 008SWS-2 | 5 |

| 33 | 898SWS-4 | 5 |

| 34 | 1012SWS-5 | 5 |

| 35 | SWS-6 | 5 |

| 36 | ARU-6 | 7 |

| 37 | SRU-2 | 9 |

| 38 | CGP-1 | 18 |

| 39 | CGP-2 | 29 |

| 40 | TPS | 34 |

| 41 | CETP | 8 |

Project Duration: 15 Months