Indian Oil Corporation Limited (IOCL) has proposed to set up a PSA Off Gas – Ethanol Plant at the premises of their existing Panipat facility.

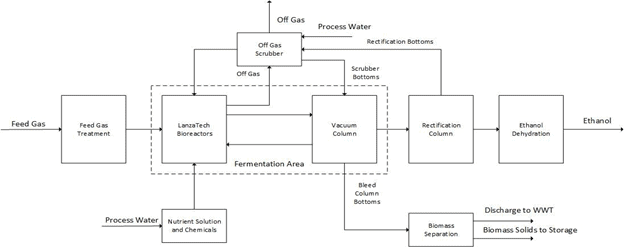

The existing premises of IOCL Panipat Refinery (PR), with a total capacity of 15 MMTPA and around 80% HS crude processing capacity has been commissioned on the basis of LanzaTech’ s proprietary gas fermentation process in which, gas streams containing Carbon Monoxide (CO), Carbon-dioxide (CO2), and Hydrogen (H2) are used to produce Ethanol.

IFluids Engineering has been entrusted by L&T Hydrocarbon Engineering Ltd. to carry out the Hazard and Operability (HAZOP) study for the LanzaTech Process Unit for Ethanol production at Panipat, Haryana.

HAZOP (Hazard & Operability) studies are conducted to aid in managing project risks through early identification of hazards and operability issues and to reduce the probability and consequences of an incident that would have a detrimental impact to any personnel, plant, properties within the scope of the facility and the off-site environment.

The scope of the HAZOP Study encompasses the general operation of all LanzaTech designed sections of the plant which includes the Cell Recycle system, Falling Film Evaporators, Dryer, Compressor packages in the PSA Off-Gas Ethanol Plant.

The overall process is designed to achieve 8,000 operating hours per year. (Process Flow diagram as show below).