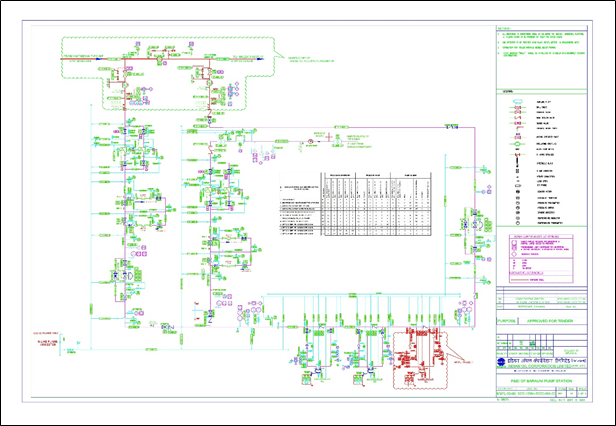

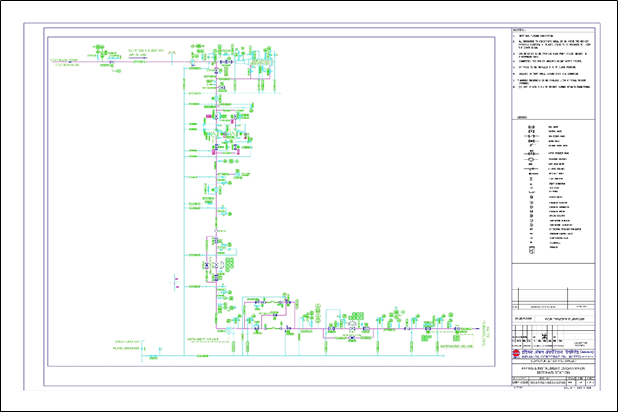

Indian Oil Corporation Limited (IOCL) has an Independent LPG Pipeline between Haldia and Durgapur with Dedicated Pumping Facilities at Haldia and Associated Facilities at Durgapur Station [PHDPL AUG] (Augmentation of Paradip – Haldia – Durgapur LPG Pipeline) and its extension up to Patna and Muzaffarpur. Project involves laying of 921 Km pipeline for transportation of LPG to consumption centre in Bihar. Pipeline traverses through state of West Bengal, Jharkhand and Bihar. Pumping facilities at Durgapur and Barauni and delivery facilities at LPG bottling plants at Banka, Patna and Muzaffarpur.

Hazard and Operability (HAZOP) Study is a technique to evaluate the potential hazards which are associated with the Existing facilities and for proposed new facilities of Operation and Maintenance. This study is carried out by a team of engineers from different disciplines. The team looks at each section of a plant or system or operation, considers potential hazards from intended operation and analyses their consequences against any existing safeguards.

HAZOP is a brainstorming technique, where team members contribution based on their collective experience and lessons learnt from their past.

HAZOP for any project or modification serves many purposes including

- Identify the hazards inherent to the proposal.

- Identify the credible human and/or equipment instrument failures likely to lead to accident scenarios/Operability Problems.

- Qualitatively assess the risk and provide recommendations to overcome the hazards if required.

- In addition to these issues, HAZOP identifies items which could improve unit operations and efficiency