iFluids Engineering conducted Gas Mapping Study for Yanpet EG2 Efficiency Improvement Project. The Saudi Yanbu Petrochemical Company, in Yanbu, Saudi Arabia modifies the existing the Unit 220 Ethylene Glycol Plant, with the goal to reduce energy consumption from 16,942 GJ/KTA EOE to 12,679 GJ/KTA EOE, a 25% reduction, achieving parity with the energy consumption of the world’s most efficient EG plants. This facility is located within the existing complex of Yanbu Petrochemical Company, in Yanbu, Saudi Arabia and this modification project was named as Yanpet EG2 Efficiency Improvement Project. Sinopec Nanjing Engineering Co Ltd awarded i Fluids Engineering to carry out Gas Mapping study for the YANPET EG2 Efficiency Improvement Project

The risk from a flammable or toxic material release is based on the probability and the potential consequence of the leak occurred. The hazardous area of this facility were identified based on the properties of the materials handled and the potential hazards in the systems which could lead to loss of containment events.

In the identified hazardous areas the potentially hazardous equipment / hazardous scenarios were identified and characterized, based on that either Toxic, Flammable gas or Fire detectors will be placed. Dispersion modelling of critical scenarios provides the basis for the detector location for minimizing the catastrophe due to release of identified flammable or toxic gas. Adequate protection using Gas detection devices shall be provided to prevent an incident from starting or from escalating. Gas Detection devices shall be provided at strategic locations where flammable gases or toxic gases are likely to occur and are likely to increase the area of detectors coverage.

The scope of work of Gas mapping services for Ethylene Glycol Unit in Saudi Yanbu Petrochemical Company includes following activities

- Revamped equipment’s in Ethylene Glycol Unit is covered for the Fire and Gas Mapping Study.

- The dispersion pattern of flammable gas toxic gas release was analysed. Based on the dispersion pattern the location and mounting height of the detectors were identified.

- To suggests the location, type and number of detectors that needs to be installed across various areas.

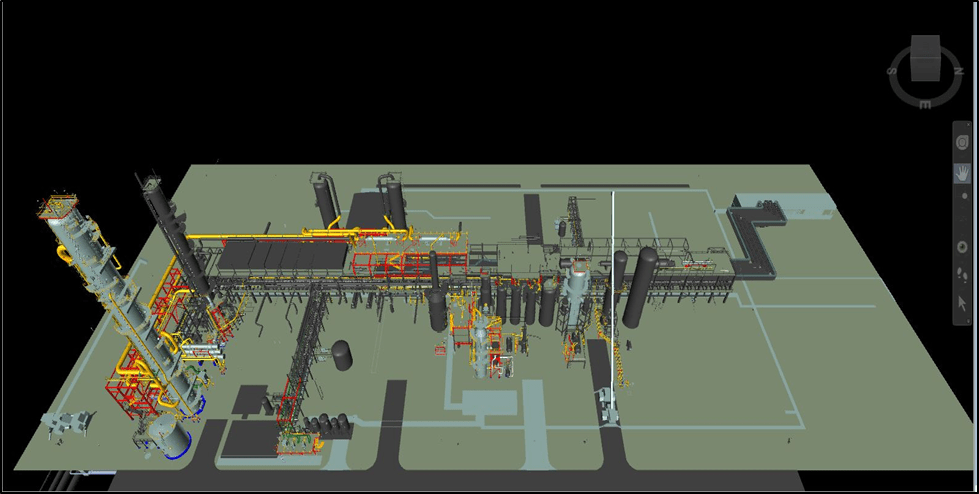

- To provide an overall Gas detection layout using the Detect 3D modelling software.

The objectives of the F & G Mapping study for the revamped equipment’s in Ethylene Glycol Unit are:

- Identifying all potential hazards that will lead to Flammable gas release or ignition and Toxic Gas release.

- By modelling the physical effect the characteristics determination of the likely gas release is done. The extent of hazardous scenario on the project facilities were assessed.

- Proposing new arrangement for fire and gas detection.