Identification and implementation of Best Available Technique (BAT) implies a balanced judgment of the benefit derived from a calculation and the cost or effort of its introduction. The level of an effort expended to resolve the issue, to record the selection process which should be directly proportional to the scale of the challenge, the range of options which is available and up to the extent to which established good practice can be performed in order to assist in the decision making process.

What is “BAT”?

BAT definition

“Best Available Techniques(BAT)” means the most fruitful and advanced stage in development of activities and methods of operation which indicates the practical suitability of particular techniques for providing the basis for emission of limit values and other permit conditions that are designed to avert while it is not practicable also to reduce emission and the impact on the environment as a whole:

– “Techniques” includes both the technology used and the way in which the installation is designed, built, maintained, operated and decommissioned;

– “Available” means those being developed on a scale which allows the implementation with a relevant industrial sector under economically and technically viable conditions, taking into the consideration of the costs and advantages may either the techniques are used or produced inside the Member State in question or not as long as they are reasonably approachable to the operator;

“Best” means the most effective way in achieving a high general level of safety in the environment as a whole. (EU’s industrial emissions directive) (Ref: 3)

Purpose:

BAT relates to the accessible techniques which are best suited for averting or minimizing emissions and impacts on the environment. It is a general requirement of environmental regulators (e.g. SEPA, EA, MECA-Oman) to make sure installations are BAT or chosen technologies which represents BAT.

Principles:

The following principles should also be taken into account when you perform BAT operation,

- Sustainable development;

- Waste hierarchy and waste form;

- The precautionary principle;

- The proximity principle.

Subject to meeting regulatory obligations, the identification and application of BAT takes into account all relevant circumstances

Few Examples of BAT Application to Process Units:

Proposed BAT for TEG-regeneration:

| New facilities | Recovery of waste gases both from the degassing tank and boiler |

| Existing facilities | Recovery is technically possible, but can have high abatement cost |

Proposed BAT for produced water treatment:

| New Installation | Recovery of waste gases both from the degassing tank CFU/traditional flotation plant and discharge caisson Reducing the pressure in the degassing tank |

| Existing Installation | Recovery is technically possible, but can have high abatement cost Reducing the pressure in the degassing tank |

Proposed BAT for dry compressor seals:

| New Installation | Internal labyrinth / no leakage from primary vent to secondary vent. Recovery of all HC barrier gases from vent openings |

| Existing Installation | Recovery is technically possible, but can have high abatement cost |

Methodology

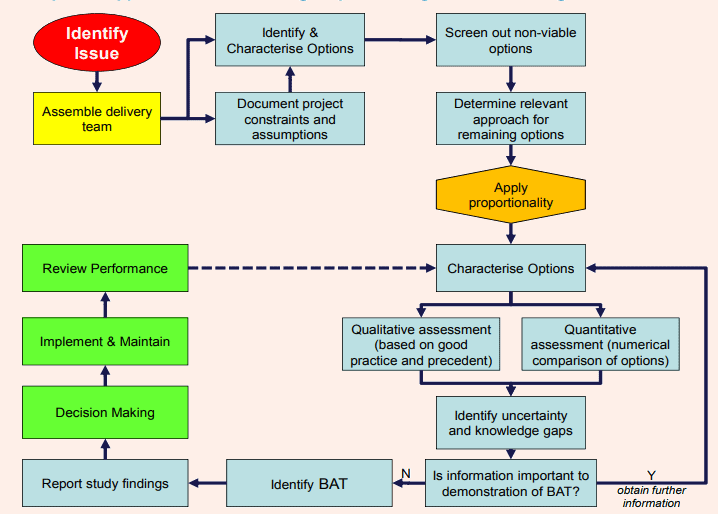

If any Significant Planned Environmental Impacts identified, BAT Assessment will be conducted. The BAT Assessment will aim at assessing the current facility design/components in order to check compliance with the Pollution Prevention and Control (PPC) principles as stipulated in relevant regulations or recognized international guidelines (e.g. EC IPPC, US EPA, IFC EHS, etc.).

In essence, as a part of this assessment, the design of the various equipment, as well as disposal techniques/issues and safety issues related to handling/storage will be audited and checked for the compliance against indicative BAT requirements with a furnished local regulations and applicable international guidelines.

Environmental input in design process will encompass an assurance that Best Available Techniques (BAT)/ Best Available Control Techniques (BACT) and with Best Practicable Environmental Option (BPEO) in handy. It is incorporated into the design and in operation at all the stages of a project. As such, a proper design appraisal will be carried out by an expertise Consultant.

iFluids Engineering details the following easy steps for systematic BAT Analysis:

Standards / Legal Framework:

- Site Specific Requirements :- Permit Conditions, Site License Conditions, COMPANY Requirements

- National Policy & Legislation :- Environmental Act / Regulation, PPC, etc.,

- International Policy & Legislation :- OSPAR Convention, IPPC Directive, Waste Directive, Basic Safety Standards, etc.,