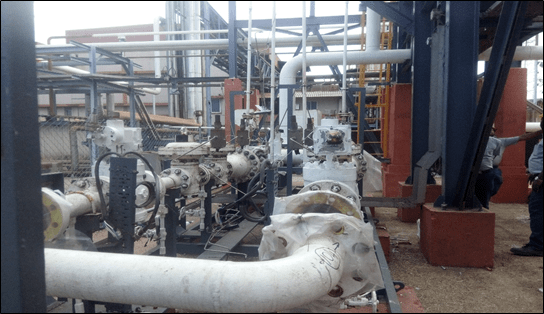

Mangalore Chemicals and Fertilizers Limited is the largest manufacturer of chemical fertilizers in the state of Karnataka. Mangalore Chemicals and Fertilizers is proposed to use Natural gas from GAIL in the various areas of the plant. MCFL has planned to provide leak detection system in the 11 areas handling Natural Gas. These area consists of Vessels, Filters, Heat exchangers, Boilers and Furnace and its associated pipelines.

This Fire & Gas mapping study is carried out to help in decision making process for locating the number of Gas and flame detectors. The fire and gas detection systems are provided on installations for prior identification of the risk from the accidental toxic and flammable gas release. The risk from flammable or toxic gas releases or fires can be reduced by early detection and subsequent mitigating actions

Eleven (11) Natural Gas handling areas including Pressure reducing station, SRV area, Heater area, Primary reformer area, Combustion chamber area, Dryer area, Filter area, Boiler area of 3 units in the site is covered for the Fire and Gas Mapping Study. The dispersion pattern was analysed to identify the location and mounting height of the detectors. Further, an overall Gas detection layout plan with the location, type and number of detectors was provided.

The main objectives of the Fire and Gas Mapping study for Mangalore Chemicals and Fertilizers Limited are:

- Identifying all potential hazards that will lead to flammable gas release or ignition.

- Determination of the characteristics of the likely gas release by modelling the physical effect and consequently quantifying the extent of hazardous scenario on the project facilities.

- Proposing new fire and gas detection arrangements.

The risk from a flammable or toxic material release is the combination of the probability of a leak occurring and the potential consequences should the leak occur. In determining the probability of a leak, the type of operation, the operating conditions, and the equipment involved are all considered. In determining the consequences, the material contained, the size of the leak, the proximity of the leak to other equipment or the fence line, and speed with which the leak might be detected without instruments are all considerations.